Sleever Machines

Take control of your product-packaging with sleeve machines for all types of shrink sleeves.

Is your packaging line or shrink sleeve machine still too slow and not efficient enough?

Discover all the options

Flexibility, user-friendliness and robustness are the key benefits of our sleeve machines. Exchange parts for different product formats make for swift and straightforward changeovers, what makes the sleeve machine ideal for sleeving small and medium volumes, and different product references.

VERTICAL PACKAGING

COMBISTEAM®

The energy-efficient steam technology offer for full body and partial decoration of soft drinks, wines & spirits, dairy , home and personal care products

COMBISHRINK®

The infra-red/ hot air offer for security and promotion of beauty, pharmaceutical, food, hygiene products, and drinks and wines & spirits

COMBISKINNER®

The hybrid infra-red/ hot air offer for full body decoration of pharmaceutical, beauty, food products, and objects

HORIZONTAL PACKAGING

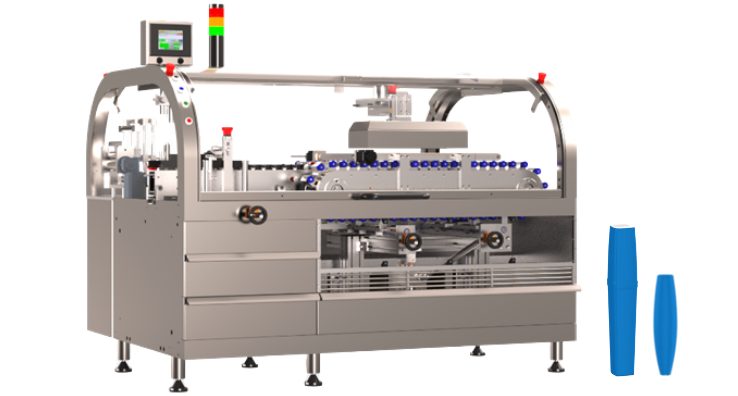

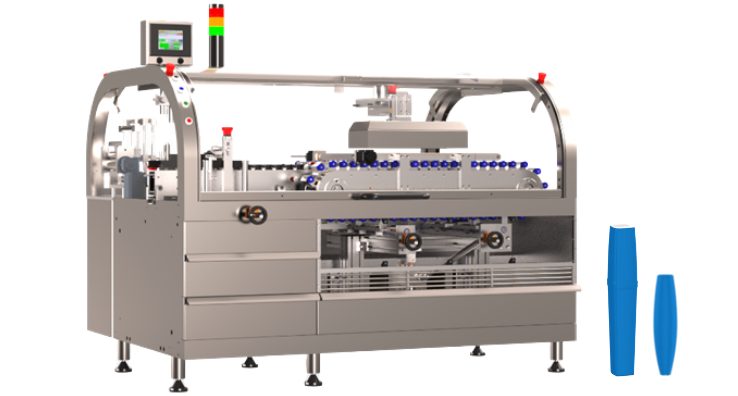

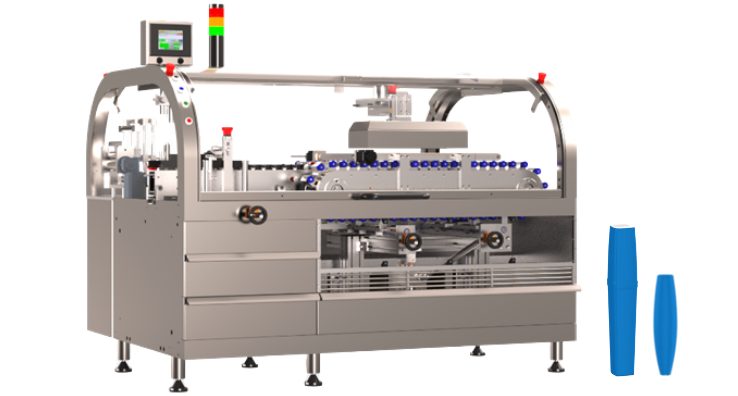

MULTIFLEX

SHRINK®

The infra-red offer for beauty, pharmaceutical, confectionary, products and objects

MULTIFLEX

SKINNER®

The hybrid infra-red/ hot air offer for full body and partial decoration of beauty, pharmaceutical, confectionary products and objects

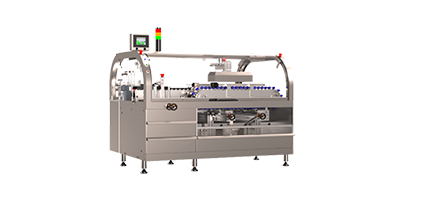

SLEEVE APPLICATOR

- Innovative design for a shrink sleeve application with flexible cutter block to process a wide range of products

- Linear or rotating applicator design for specific sleeve applications or cadences

- Product in various forms, round, oval or square, can be sleeved on our standard machines

- Fully automatic sleeve machine applicator, PLC controlled set-up and pneumatic fixing system for shorter changeover times

Is your packaging line still too slow and not efficient enough? Discover all the options

HEAT SHRINK TUNNELS

STEAM SHRINK SLEEVE TUNNELS

- Patented ‘Multi-compartment’ steam shrink sleeve tunnel with

- Standard external ‘Easy Access’ spindle control for easy adjustment

- Standard ‘Easy View’ peepholes in the doors for visual monitoring of the sleeve shrinking process

- Optional ‘Super Dry’ overheated steam supply system for specific sleeve applications requiring very dry steam

- Fully automatic PLC-controlled temperature control and electronically controlled steam supply and exhaust, to guarantee a constant temperature

- Optional spindle controls automation with PLC controlled stepper motors for ultra-short changeover times

- Integrated electrical or stand-alone gas-fuelled steam generator

ELECTRICAL TUNNELS

- Electrical tunnel with infrared panels and hot-air blowers to ensure precise, smooth and gradual shrinking.

OPTIONS

For specific sleeve applications or product handling, we can include following options:

- automatic loading systems for aligned products with the shrink sleeve machines

- underlap or undersleeve system to avoid smiley effects

- fully automatic set-up of all manual controls, including the shrink sleeve machines, sleeve applicators and heat shrink sleeve tunnels

- fully automatic roll switching without sleeving machine stop

- etc.…

SERVICES

Whether your sleeve line or shrink sleeve machine is stand-alone or fully integrated with other shrink tunnels or sleeve applicators, Helios Packaging takes care of the delivery, the installation and start-up of the entire sleeving production line.

Furthermore, you can count on our team to provide assistance and to adjust your system when changing over to a new product.

Thanks to our strategic location, in-house technical service and stock of spare parts, you can always rely on us for quick interventions and a professional after-sales service.

Flexibility, user-friendliness and robustness are the key benefits of our sleeve machines. Exchange parts for different product formats make for swift and straightforward changeovers, what makes the sleeve machine ideal for sleeving small and medium volumes, and different product references.